Dinnerbell Farms is located in Eden, Wisconsin, and is owned and operated by the Grahl family, milking 275 cows. They have partnered with Vanguard Renewables, a Boston-based sustainable waste management and clean energy company, for construction and operation of an anaerobic digester that will harness the farm’s manure as well as off-site food waste to create energy — specifically renewable natural gas. This anaerobic digester will produce 710 MM btu or 208,000 kWh per day, which will contribute directly to the distribution gas pipeline network and supply 4,200-6,300 homes per year with reliable natural gas.

MSA was asked to assist with multiple disciplines of the project, including site civil design for the digester site including stormwater design, permitting, and structural design for a new digestate storage facility. The site is approximately 10 acres of improvements including an organics receiving area, anaerobic digester, and associated components such as hydrolysis tanks and biogas upgrader, metering and regulation pad for grid injection, digestate storage and stormwater management features.

The first component of the Eden digester project involved navigating numerous challenges to site a digestate storage. A predetermined lease area partnered with a property line setback presented a challenge in providing sufficient storage volume within a small footprint. This was complicated by a large amount of grade change across the site. A sandy subsoil morphology pushed the project to utilize an American Concrete Institute (ACI) 350 environmentally sensitive concrete design.

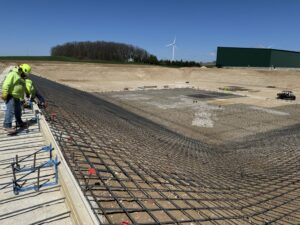

MSA agricultural engineers proposed construction of a 116,160-square-foot new watertight concrete manure “tangoon” — a combination of a traditional lagoon and vertical wall tank — with 18’ deep sloped walls, topped with an 8’ vertical wall. This provides the farm with 6.5 months of available storage at a usable storage volume of 17.1 million gallons.

Structurally, the tangoon design consists of a typical straight retaining wall with a footing that transitions into the sloped side walls of the lagoon. The tangoon also has an entrance ramp at the northwest corner.

A few design challenges arose during the project, such as at the connection joint between the retaining wall footing and the lagoon side wall. The retaining wall footing had limited width due to nearby structures and required a sliding restraint from the lagoon slab. To resist sliding, the lagoon slab was raised, flattened, and thickened to match the wall footing. This provided enough concrete to dowel the footing without cracking the thinner lagoon slab. Footing reinforcement was carried across the joint and lapped with the lagoon reinforcement. Additionally, for constructability, the ramp side walls used the same wall and footing design as the retaining wall. All structural elements were designed in accordance with ACI 350 standards pertaining to maximum reinforcement spacing, temperature and shrinkage, slab and wall thicknesses, etc.

MSA engineers also worked to provide a site design for the provided layout of the digester site that met the owner’s needs for access, traffic flow, permitting requirements, and safety — and accommodated stormwater requirements while fitting all components within the specified lease area. A special component was designed for the truck liquid offloading area for food wastes as well as an intricate truck scale design within a limited footprint.

Other MSA-designed components included the transfer system from Dinnerbell Farm’s existing under-barn manure storage system, a sand separation system in partnership with Komro Sales & Service, and a loadout station for manure tankers to easily collect digestate for land application.

This project was selected to receive a 2024 Concrete Design Award in the Agricultural category from the Wisconsin Ready Mixed Concrete Association (WRMCA).