Meeting the Solids Management Challenge

Municipal wastewater treatment plants face continuous pressure to manage solids in a way that balances performance, regulatory compliance, and budget. Digested sludge, in particular, poses a challenge due to its low solids content and high-water volume. This makes storage and hauling costly and inefficient without proper dewatering. Traditional mechanical dewatering methods, such as presses or centrifuges, may be too expensive for specific communities. Additionally, ongoing operational demands and maintenance for these systems can quickly consume limited staffing and resources.

Geotextile dewatering provides a simple yet innovative and cost-effective solution for managing biosolids. These passive dewatering systems enable communities to reduce the volume of solids while avoiding the need for complex infrastructure. For many rural and mid-sized municipalities, this approach represents an ideal balance between affordability and performance.

Understanding Geotextile Dewatering Technology

Geotextile tubes are long, cylindrical containers fabricated from high-strength, permeable polypropylene fabrics. The technology allows water to pass through the walls of the material while retaining solids inside. These fabrics are selected not only for their strength but also for their specific filtration capabilities, which are key to achieving clean filtrate and effective solids retention.

In a typical application, sludge is conditioned with polymers to promote flocculation, then pumped into the tubes. As the tubes fill, water seeps through the geotextile fabric and is collected, where it is returned to the plant’s headworks. The remaining solids consolidate over time through passive gravity drainage, aided by environmental factors such as freeze-thaw cycles and evaporation. The dewatered solids can be stored in the tubes for weeks, months, or years, depending on operational needs, before being removed and either disposed of or applied to land.

Advantages of Geotextile Tube Dewatering

Geotextile tube systems offer multiple advantages that make them attractive for municipalities facing solids management challenges. These benefits include both economic and operational efficiencies.

Key benefits include:

- Reduced hauling costs due to lower water content in dewatered solids.

- Low capital investment compared to presses, centrifuges, and dryers.

- Minimal operator input: no moving parts beyond pumping and the polymer system.

Wisconsin Case Study: Monitoring Performance Over Time

To evaluate long-term performance, MSA partnered with a Wisconsin municipality to monitor a newly constructed geotextile tube dewatering facility. This research is just one example of MSA’s commitment to applied engineering and real-world monitoring. The research effort included sampling during both the filling and consolidation phases. Led by MSA staff and a student intern, the project provided a detailed look at how biosolids dewater and consolidate over time.

During active filling, aerobically digested sludge from a sludge holding tank was pumped into the tubes. Polymer was added to enhance flocculation. Samples were collected from both the influent and the filtrate. Composite samples were then analyzed to assess initial solids concentration and the quality of the filtrate returned to the head of the plant.

After filling concluded, the geotextile tubes were left to dewater for one hour before collecting core samples using a soil sampling stick. An 18-inch core was extracted from two sampling ports. Initially, tubes were tested weekly for four weeks, then transitioned to monthly sampling as consolidation stabilized.

Research Findings

Lab analyses revealed that the sludge entering the tubes contained between 1.1% and 4.3% total solids. As expected, solids concentration increased significantly during the consolidation period. Samples collected during intermediate testing showed solids content as high as 15%. By the time solids were removed for landfill disposal, total solids concentration had increased to nearly 26%.

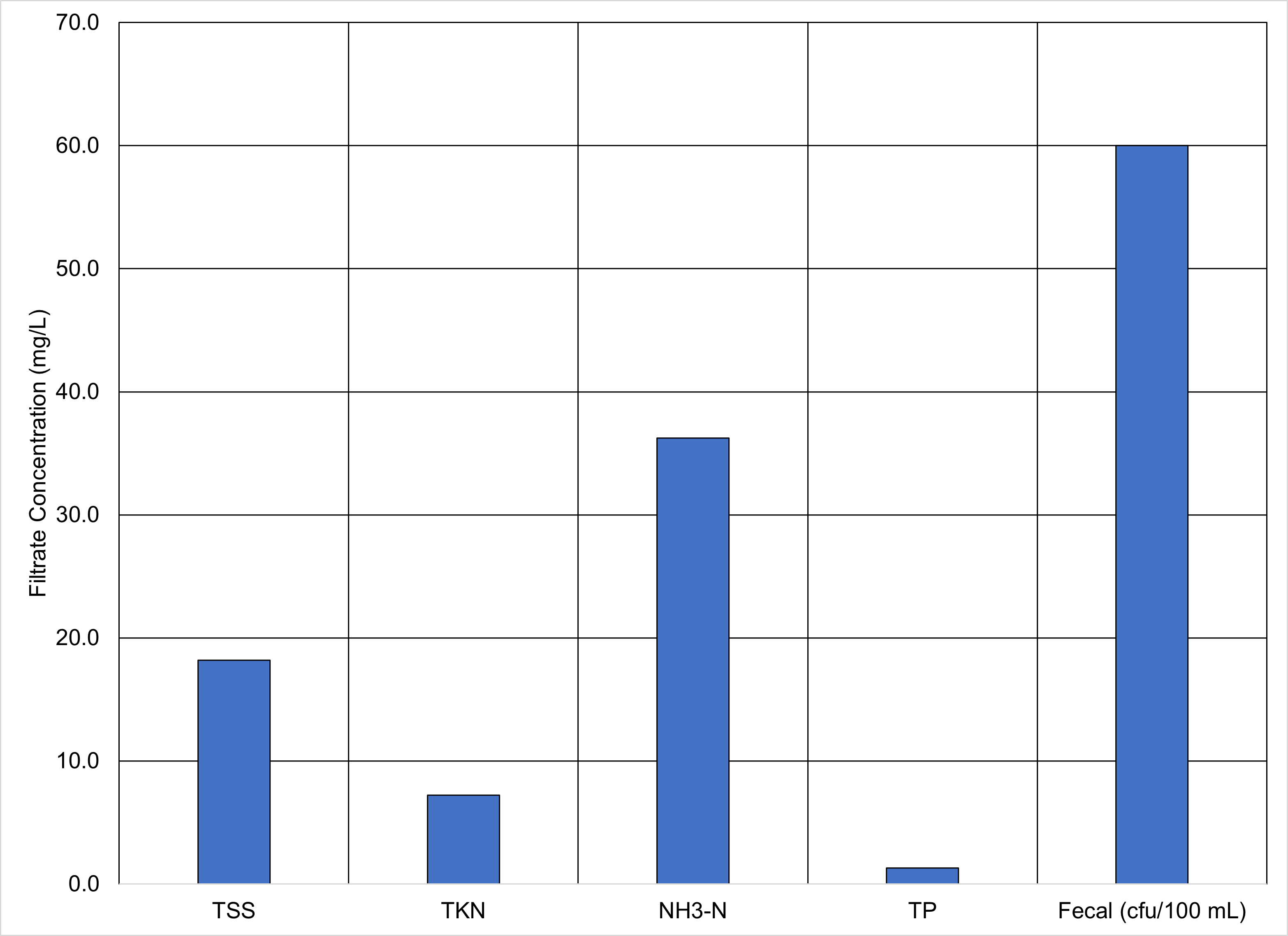

The filtrate quality was also notable. Across all composite samples collected during the filling phase, the total suspended solids (TSS) in the filtrate averaged below 20 mg/L, which is well within acceptable sidestream TSS removal rates for most facilities.

Conclusion

Geotextile tubes continue to prove themselves as a low-cost, low-maintenance method for biosolids storage and dewatering. Their simplicity and scalability make them especially attractive for small- to mid-sized municipalities looking for alternatives to traditional mechanical systems. This case study demonstrates that, with proper planning and monitoring, geotube systems can achieve consistent solids reduction, clear filtrate, and long-term performance gains.

While geotextile tube technology may not be flashy or cutting-edge, it offers something far more valuable to many communities: practicality. For municipalities facing increasing challenges with limited budgets, aging infrastructure, and constrained staffing, this solution delivers reliable, cost-effective results without operational complexity. At MSA, we specialize in identifying and implementing these kinds of grounded, data-driven solutions — ones that make a measurable difference in the day-to-day operations of our clients. Because real-world challenges require real-world answers.